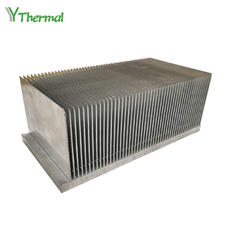

Material: copperSize:54*50*46mmWeight: 0.464kgTechnology: Skiving finFeature: Higher cooling power and better conductivitySurface treatment: PassivationHeat cooling power: 168WWelcome to buy Copper Skived Process Fins Heat Sink Fins for High Power Thermal Solutions from us. Every request from customers is being replied within 24 hours.

Product parameters of Copper skived process fins heat sink fins for high power thermal solutions

Material: copper

Size:54*50*46mm

Weight: 0.464kg

Technology: Skiving fin

Feature: Higher cooling power and better conductivity

Surface treatment: Passivation

Heat cooling power: 168W

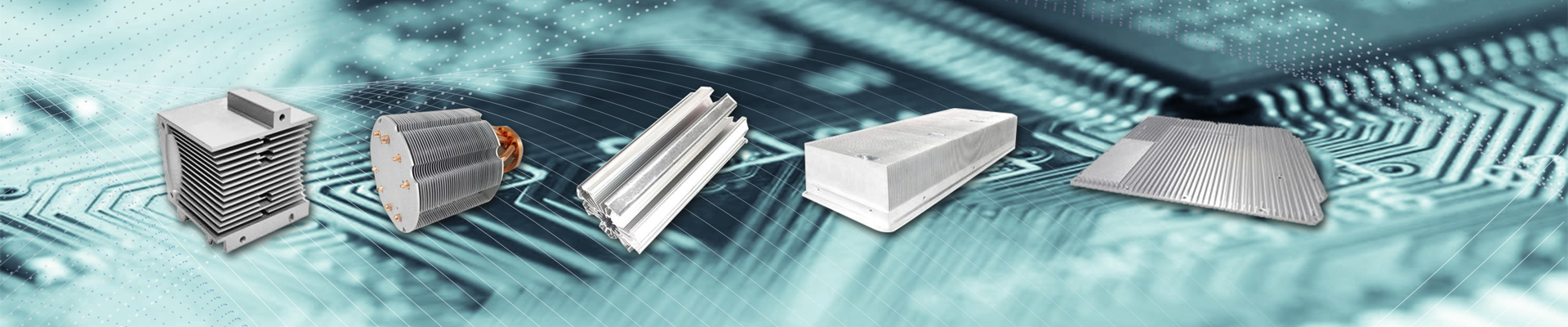

Product advantage of Copper skived process fins heat sink fins for high power thermal solutions

Skiving fin is the process of relieving Al teeth. The profile is processed into a specific model, such as radiator, etc. with the skiving fin machine tool, the finished product is the skiving fin heat sink.

The skiving fin heat sink is a kind of gap structure with the same sequence formed by cutting the material out of a certain angle by mechanical action of the strip profile (aluminum and copper). It is used to solve the heat dissipation of high-power devices under the condition of air cooling and heat dissipation, and its heat dissipation efficiency can be increased by 8-15% compared with the other heat sink.

With the large-scale application,our skiving fin radiator technology are more mature, the level of automation is gradually improved, our cost and reliability advantages are remarkable. It is used in UPS, base station, charging pile, frequency converter, controller, wind power converter, SVG, LED lamp.

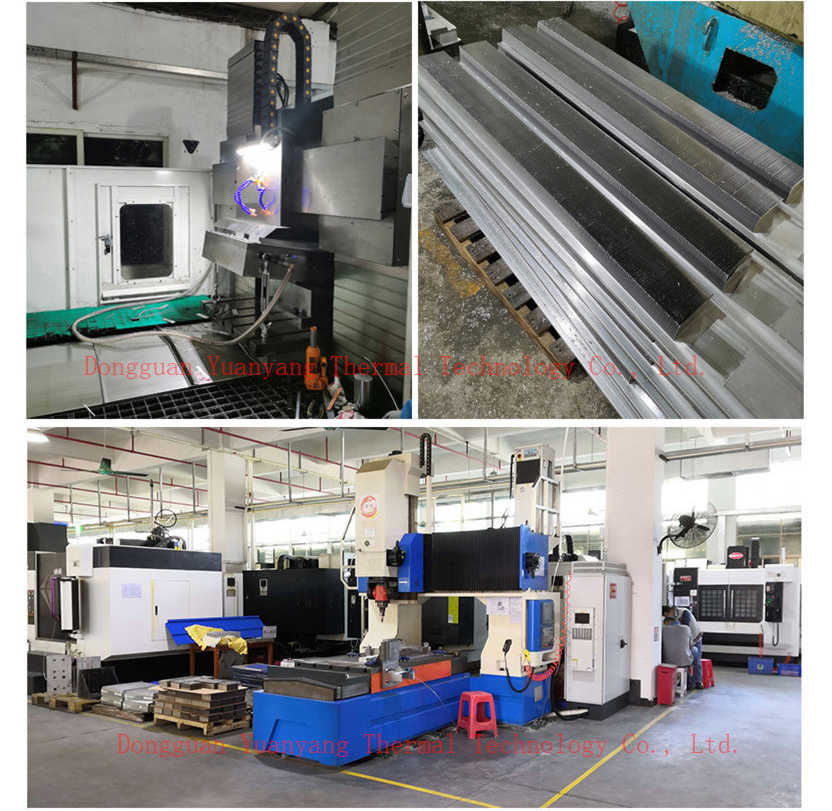

Our machines:

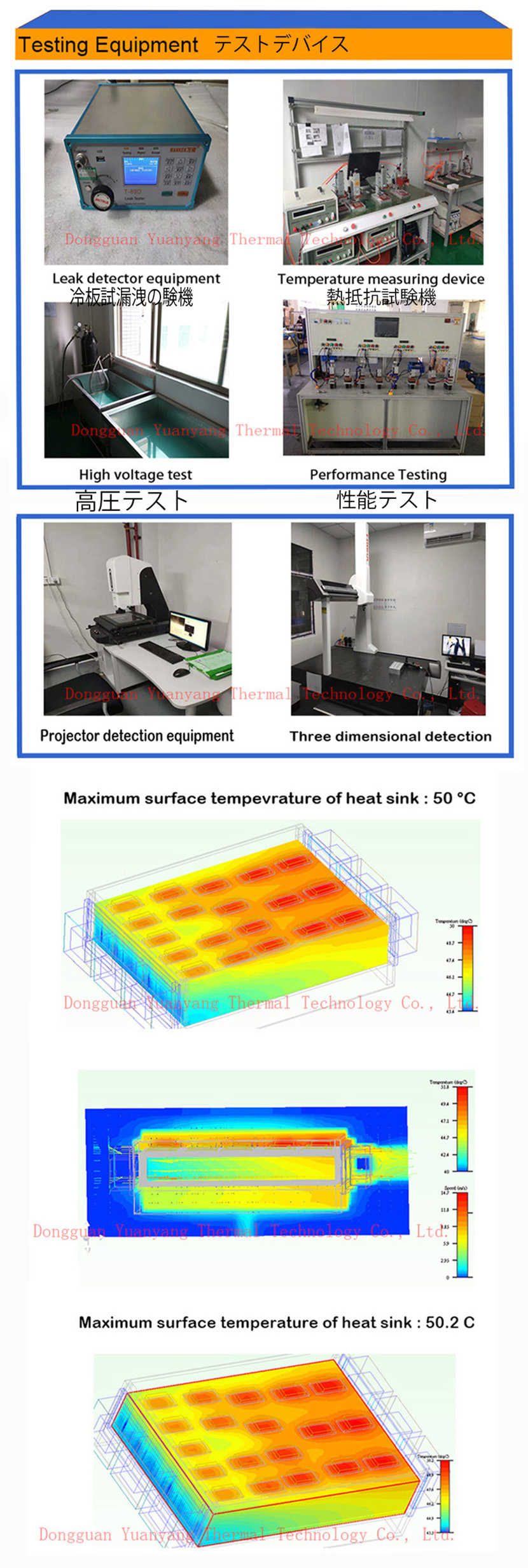

Our testing machines:

Our soldering assembly line:

Our team:

We as a team,move forward and backward together;

We have good services,high efficiency and great development;

We are market -sensitive and have strong will for the modern market.

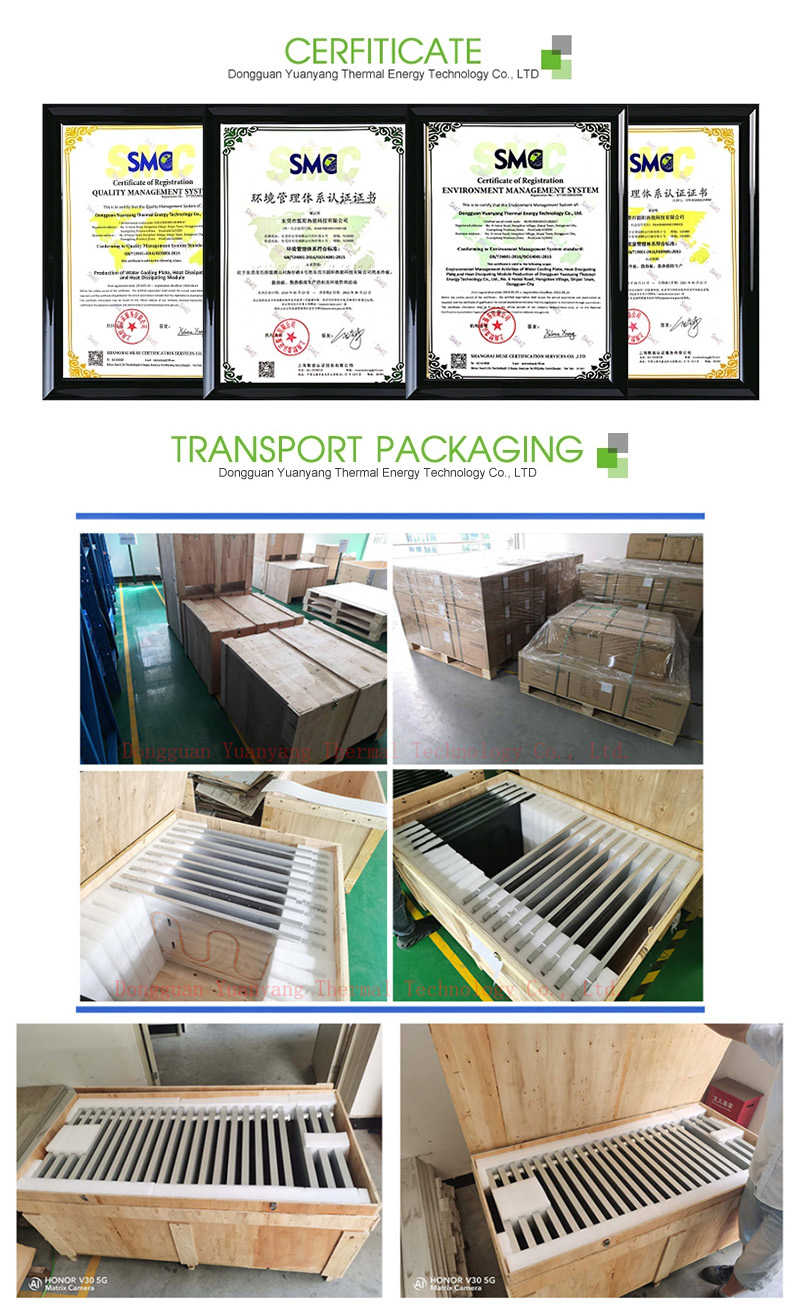

Our Certificate

Our service:

1.Once received the inquiry will be quickly replied

2.Keep the product be qualified and price be reasonable and competitive.

3.Fastly arrange production and improve efficiency.Get the goods be finished on time.

4.We can advice the best transportation depends on the goods weight and cubic meter

5.Any questions with the goods we made, we will offer the best solution and technique support.

FAQ

1. Q:Are you trading in company or manufacturer?

A:We are the professional manufacturer of heat sink and water cooling plate that has much experiences and strong technique team,automatically and mechanized production

2. Q:Have you exported the goods before and to which regions?

A:60% goods in total has exported abroad,to Japan,India,British,Canada,America and Brazil.

3. Q:How many employees you have?

A:we have about 100 employees,including sales,purchase,engineering,QA,warehouse and production department.

4. Q:If I agree with the design,can you provide the samples we need?

A:Yes,we can.we surely will provide the samples to you for confirmation before mass production.Meanwhile the drawing we could provid if needed

5. Q:What packing you're using and can be assured safty?

A:Every goods are be packed with customized packing ways in normal cartons with tight proof fabric and wooden cartons for great protection, so it is safe during transportation.

6. Q:If we have any questions with products,can you provide the technique and solution?

A:Every products are fully checked before shipping, if there is problems you're facing,please feel free to let us know,we will offer best solution at once.

Aluminum Skiving Or Skived Heatsink With Anodized Black For Industrial Pcb Board

Aluminum Skiving Or Skived Heatsink With Anodized Black For Industrial Pcb Board

Aluminum Skiving Heat Sink For Electrical Power Supply

Aluminum Skiving Heat Sink For Electrical Power Supply

Aluminum Material Skived Fin Heat Sink Thick Coarse Fin Skiving Fin Heatsink

Aluminum Material Skived Fin Heat Sink Thick Coarse Fin Skiving Fin Heatsink

Aluminum Skived Fin Heat Sink CNC Machined Skiving Fin Heat Sink

Aluminum Skived Fin Heat Sink CNC Machined Skiving Fin Heat Sink

Aluminum Skived Fin Heat Sink CNC Milling Machined

Aluminum Skived Fin Heat Sink CNC Milling Machined

2u Copper Profiles Skiving Fin Heat Sink Copper Product Heatsinks

2u Copper Profiles Skiving Fin Heat Sink Copper Product Heatsinks